ISSN: 2320-5407

Int. J. Adv. Res. 6(5), 1086-1095

Journal Homepage: -

www.journalijar.com

Article DOI:

Article DOI: 10.21474/IJAR01/7132

DOI URL: http://dx.doi.org/10.21474/IJAR01/7132

RESEARCH ARTICLE

AQUATIC ECOSYSTEM MONITORING REMOTE VEHICLE.

1.

2.

Dabholkar Aakshay V1, Takade hiraj D1, Todkar Premraj S1 and Dr. V. Jayashree2.

Undergraduate Students at DKTE Society’s Textile & Engineering Institute, Ichalkaranji.

Professor Electronics at DKTE Society’s Textile & Engineering Institute, Ichalkaranji.

……………………………………………………………………………………………………....

Manuscript Info

Abstract

…………………….

………………………………………………………………

Manuscript History

Received: 18 March 2018

Final Accepted: 20 April 2018

Published: May 2018

Key words:AEMV, pH, aqua culture, ATMega328,

Central Monitoring Unit, Aqua

Monitoring Unit.

This paper reports the Underwater Vehicles for Surveillance and

Monitoring Aquatic Ecosystem. The acceptable range of pH for aqua

environment is between pH 6.0 to pH 8.0. Different problems

associated with aquatic ecosystem due to water pollution are

increasing pH and temperature due to global warming and decrease of

dissolved oxygen. This is endangering the various aquatic species.

Besides this, water becomes unusable for drinking, farming and for

general work. So a microcontroller based un-manned vehicle for

monitoring the water purity parameters viz.; pH and temperature using

wireless communication is presented here. It has a aqua monitoring

unit which continuously monitors the purity of water and sends an

alarm to the central monitoring unit in case the water turns abnormal

acidic/alkaline and gives an information on speed of wind, floating

debris, possibility on earth quake through earthquake signals sensed in

water etc. This helps for ensuring the safety of aquaculture as well as

human being.

Copy Right, IJAR, 2017, All rights reserved

……………………………………………………………………………………………………....

Introduction:-

The ocean occupies approximately 71% of the earth surface and still has a lot of unexplored parts. Therefore,

various studies and development about the ocean such as marine environment, earthquake, ocean life, and marine

resources research and so on are carried out. Plenty of survey data and observation of the actual sea is available for

the studies and the development. Remotely operated vehicle can play an important role in monitoring, protecting and

maintaining the aquatic ecosystem which is polluted by waste chemicals from factories, oil spilling in oceans,

accidents caused due to ships etc. Hence there is a need of a low cost, highly efficient underwater vehicle which can

serve multiple applications. Indian aquaculture is facing a number of problems today. Indian shrimp production went

low to 2% of total world shrimp production and contributed to an export of 1730 million dollars in 2009. There are

several reasons for such a low production. The acceptable range of pH for aqua environment is in the range of pH

6.0 to pH 8.0. When pH of water is above 9, then it is very alkaline, then ammonium in water is converted to toxic

ammonia, which is dangerous to survival of shrimps. On the other hand, pH of water below 5 makes it acidic water

which leeches metals from rocks and sediments. The correct pH, alkalinity and hardness are essential for a

successful aqua life where fertilizers containing nitrogen, phosphorous and potassium are added to encourage the

growth of aqua culture.

Anuradha A. Maindalkar, Saniya M. Ansari designed an instrumentation for underwater vehicle using a wireless

module, and software for real-time in-field sensing and control of a site-specific precision system. The conceptual

Corresponding Author:- V. Jayashree.

Address:-DKTE Society’s Textile & Engineering Institute, Ichalkaranji.

1086

�ISSN: 2320-5407

Int. J. Adv. Res. 6(5), 1086-1095

layout is useful for the transmission and reception of information through wireless module [1]. A low Cost Remote

Controlled Underwater Rover is useful for studying the underwater life and all the underwater activities to learn

about the underwater life[2]. In paper by G. Divya Priya and Mr.I. Harish describes an application of a wireless

module and Raspberry Pi for low-cost wireless controlled underwater vehicle that removes the need for

workmanship for monitoring water resources for its pollution. The Arduino an Embedded Computing platform, uses

the hardware and software that can interact with it’s environment [3]. Koushik Reddy, et al. have reported the

details about Dissolved Oxygen sensor, PH sensor, Ultra Sonic Sensor etc. which are connected to a base device

called Arduino Board. The device automated using the internet. The conceptual layout is useful for the design of

aquatic ecosystem monitoring vehicle [4]. Underwater Remotely Operated Vehicle (ROV) for a shallow water

environment (up to 10m depth) was developed using Fuzzy Logic motion control and electronic power control. The

main controlling unit of the electronics is a Raspberry pi microcomputer operates the video. Very satisfactory

operation were observed for test trials of the ROV conducted in a laboratory water tank to a depth of about 1.5 m[5].

An autonomous underwater vehicle (AUV) an interdisciplinary coastal research was deployed to collect chlorophyll

fluorescence, optical backscattering (880nm), and physical data. It sampled the region to quantify various features in

both physical and bio-optical properties in the Bays[6].

Based on the literature survey, we aim to develop & implement aquatic ecosystem monitoring system for aqua

culture of shrimps by monitoring the water purity parameters such as pH, and temperature of water using wireless

communication for ensuring the safety for aquaculture as well as human being.

Methodology:A. Block Diagram of Aquatic System

Figure 1 shows the block diagram of our project. This figure gives the requirement of the system i.e. microcontroller

block, LCD, sensors, battery bank and mechanical arrangement.

The block diagram of our project consists of mainly two parts, viz., Part-1 consists of central monitoring unit and

Part-II Atmega based aqua monitoring unit is as shown in Figure 1. Different subblocks of the system are as follows,

a) Arduino with ATmega 328. 2)Temperature sensor, 3)pH sensor, 4)Wind speed sensor, 5)Vibration sensor,

6)Ultrasonic sensor, 7)LCD display, 8)Zigbee Module, 9)DC motor and mechanical assembly , 10)Battery bank.

1) ATmega 328 microcontroller:

The purpose behind the selection of ATmega 328 microcontroller is that it is very simple to use and very powerful

device. It has in built ADC section, 8 and 16 bit timer section, watch dog timer, Low voltage programming and

PWM control.[7].

2) Temperature sensor: Temperature sensor DS18B20 is used to detect temperature of water resource. It is a

smart digital temperature sensor which gives 12 bit digital output with resolution of 0.069v/0C. It works at low

voltage and gives precise temperature values.

1087

�ISSN: 2320-5407

Int. J. Adv. Res. 6(5), 1086-1095

Central monitoring Unit

Unit

Personal

Zigbee

Wireless communication

Water

Pollution

Departm

Computer

(Database)

Aqua

monitoring

Unit

Piezo

Sensor

Wind

Sensor

Battery

Bank

Temperature

Sensor

ATmega 328

(UVSMA&E )

pH sensor

Motor

Driver

Left

Motor

Right

Motor

LCD

Display

Zigbee Module

(Rx/T

Aquatic

Robot

Figure (1):- Block diagram of implemented system

3) pH sensor: pH sensor is used indicate the acidity/alkalinity of a water resource. CSL 31 is an analog sensor

with glass body, refillable, ceramic diaphragm pH electrode with low noise co-axial cable.

4) Wind speed sensor: Wind speed sensor used in this project is a 5V DC voltage which generates dc voltage

in accordance with wind speed. By using a standard formula we can calculate the speed of air.

5) Vibration sensor: Vibration sensor based on Piezo-electric principle is used to detect the turbulence of water

resource. It produces voltage proportional to the vibration present around the aquatic vehicle.

6) Ultrasonic sensor: Ultrasonic sensor is used to detect the obstacles coming in front of AEMV which

produces a trigger pulse and echo pulse to detect the obstacle. If the obstacle is too close to AEMV, then

AEMV gets automatically reversed.

7) LCD display: LCD is used to display the measured values of temperature and pH of water with the help of

16X2 LC.

8) Zigbee Module: Aquatic signals monitored by AEMV are sent to central unit to using wireless control.

Hence, Zigbee module CC2500 is used as the wireless transmission and reception of data.

9) DC motor and mechanical assembly: DC motors operating at 12 volts are used for the movements of

AEMV such as forward, backward and left, right movements. Also we require geared DC motors along with

appropriate DC driver IC i.e. L293D. Also some mechanical arrangement is used for the movements.

A. System Requirement

1)

In this, arduino development board is used to dump the aqua monitor code in the IC ATmega328.

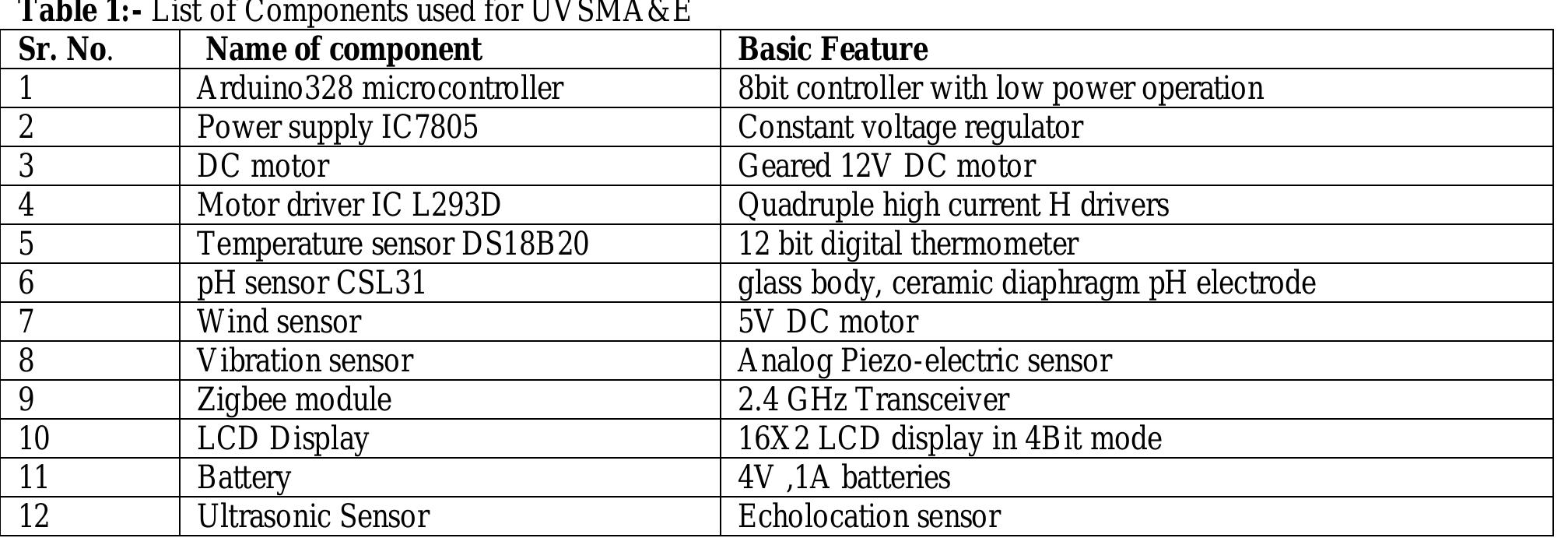

Components used for AEMV are tabulated in Table I.

1088

�ISSN: 2320-5407

Int. J. Adv. Res. 6(5), 1086-1095

i. DC motor : DC motor with operating voltage of 12.0VDC output, Speed of 30 +/- 10% RPM, No-Load output

current is less than 50 mA, Rotation Output has noiseless Gear with clockwise and counterclockwise motion.

and No-Load Speed of 5700 RPM & No-Load Current of 30Ma

ii. Motor driver IC L293D: As arduino328 is a low power device, driver IC, The L293D is designed to provide

bidirectional drive currents of up to 600-mA at voltages in the range of 4.5 V to 36 V. All inputs are TTL

compatible. A high enable input enables the associated drivers and make their outputs are active and in phase

with their inputs.

Table 1:- List of Components used for UVSMA&E

Sr. No.

Name of component

1

Arduino328 microcontroller

2

Power supply IC7805

3

DC motor

4

Motor driver IC L293D

5

Temperature sensor DS18B20

6

pH sensor CSL31

7

Wind sensor

8

Vibration sensor

9

Zigbee module

10

LCD Display

11

Battery

12

Ultrasonic Sensor

iii.

iv.

v.

vi.

Basic Feature

8bit controller with low power operation

Constant voltage regulator

Geared 12V DC motor

Quadruple high current H drivers

12 bit digital thermometer

glass body, ceramic diaphragm pH electrode

5V DC motor

Analog Piezo-electric sensor

2.4 GHz Transceiver

16X2 LCD display in 4Bit mode

4V ,1A batteries

Echolocation sensor

Temperature sensor: A water resistant temperature sensor which gives precise temperature readings at low

power supply digital sensor, DS18B20 which is very accurate and operates at 5V supply voltage. The

digital thermometer (DS18B20) has 9-bit to 12-bit Celsius temperature measurements and has an alarm

function with non volatile user programmable upper and lower trigger points. The DS18B20 communicates

over a 1-Wire bus for communication with a central microprocessor. For water resistance feature this

sensor is enclosed in steel bar[10].

Power Supply Range: 3.0V to 5.5V ,Temperatures Range: -55°C to +125°C (-67°F to +257°F) , ±0.5°C

Accuracy from -10°C to +85°C , Thermometer Resolution is User Selectable from 9 to 12 Bits, Converts

Temperature to 12-Bit Digital Word in 750ms (Max)

pH sensor Operating Temperature: 0°C to 100°C Response Time: <10 seconds for 95% response from 7

pH to pH 4.01, has a Glass Membrane Impedance of 200 M, sustain Pressure: Upto 87 psi, and measure pH

range: 0 to 14.00 pH[10].

Wind speed sensor: For the constant flow of water, it is required to have constant air flow surround water

resource. To detect the wind speed, a 5V dc motor with turbines is used. Whenever the air flow appears

across turbines, turbines starts rotating and creating a dc voltage. This voltage value is taken as input and

by using a standard formula in (1) the wind speed in meter/seconds is computed. The formula used to

derive wind speed is as follows.

SensorVoltage=SensorValue*VoltageConversionConstant

windspeed=(sensorVoltage*10)/(2.223694)

Where,

voltageConversionConstant=0.004882814

a

b

Figure(2):- a) Wind Speed Sensor b) Vibration sensor

(1)

(2)

(3)

Figure(3):- Ultrasonic Sensor

1089

�ISSN: 2320-5407

Int. J. Adv. Res. 6(5), 1086-1095

vii.

Vibration sensor: As the epicentre of maximum earthquakes are in water resources, so a vibration sensor

has been used to detect sudden change in water turbulence. AEMV will be rerouted and it will sank in

water. A piezo-electric sensor is used to detect the turbulence which is simple and has high sensitivity.

viii.

Ultrasonic distance sensor : Invento INVNT_8 Ultrasonic Module Hc Sr04 is a precise, non-contact

distance measurements from about 2 cm to 3 meters. It requires only two I/O pins of Propeller chip, or

Arduino. This sensor transmits a burst in the form of an output pulse that corresponds to the time

required for the burst echo to return to the sensor. Measurement of the echo pulse width, helps to

compute the distance to target. Specifications are as further.[11]

o Ultrasonic Range is from 2 cm to 3 m, has a burst indicator LED to show sensor activity.

o It has a bidirectional TTL pulse interface on a two I/O pins can communicate with 5 V TTL or

3.3 V CMOS microcontrollers.

o Input trigger is a positive TTL pulse of 2 μs minimum typ

o Echo pulse is a positive TTL pulse, with 10 μs to 18.5 ms.

o Supply voltage requires +5V DC Voltage and Supply current: 30 mA typ & 35 mA maximum.

o Communication uses Positive TTL pulse.

RF Transceiver CC2500: A transceiver CC2500, a low-cost, 2.4 GHz transceiver designed for very lowpower wireless applications is used in this project[10]. The circuit is intended for the 2400-2483.5 MHz

Industrial, Scientific and Medical(ISM) and Short Range Device(SRD) frequency band. The RF

transceiver is integrated with a highly configurable baseband modem CH341SER. The modem supports

various modulation formats and has a configurable data rate up to 500 kBaud. The main operating

parameters and the 64-byte transmit/receive FIFOs of CC2500 can be controlled via an SPI interface.

[10]

ix.

Figure(4):- RF Transceiver CC2500

o

o

o

o

o

o

o

o

Has a Frequency range : 2400 – 2483.5 MHz

High sensitivity of 104 dBm at 2.4 kBaud, 1% packet error rate.

Low current consumption of the order of 13.3 mA in RX, 250 kBaud, input well above sensitivity

limit.

It has a Programmable output power up to +1 dBm and excellent receiver selectivity and

blocking performance with Programmable data rate from 1.2 to 500 kBaud.

Small size (QLP 4x4 mm package, 20 pins) Supports for asynchronous and synchronous serial

receive/transmit mode for backwards compatibility with existing radio communication protocols.

Takes only 400 nA SLEEP mode current consumption with fast startup time of 240 us from

SLEEP to RX or TX mode

Wake-on-radio functionality for automatic low-power RX polling

It has a Separate 64-byte rx and tx data fifos

Battery: A power supply of 12V, 1A is designed to drive i)the motor which needs 600mA current and ii)to

drive the wireless module CC2500 which needs 20mA current and iii) for different sensors. Hence,

rechargeable Li-ion batteries of 4V and 1A in series to provide a supply of 16V, 1A is used here.

System implementation:A. Hardware Implementation:

In this project ATmega328 microcontroller, temperature sensor, pH sensor, wind speed sensor, piezoelectric sensor

and 16X2 LCD for displaying different parameters are used.

1090

�ISSN: 2320-5407

Int. J. Adv. Res. 6(5), 1086-1095

1) Selection of ATMega328 pins for peripheral interfacing

Table II gives the detail of the port pins of ATMega328 controller used for interfacing the peripherals such as ADC,

LCD, Motor driver, sensors etc. The component used, port pins of Arduino, for interfacing various pins of

components are tabulated in Table II. Total of 18 port pins of processor are used for this purpose.

TABLE II:- Details of Interfacing to ATMEGA328

Port Pin

Function

18

Port B pin used as general I/O

17

11,6,5,4

26

Port C pin as Analog I/P

25

Port C pin as Analog I/P

24

Port C pin as Analog I/P

28,27

Port C pin as general I/O

16,15

Port D pin as

general I/O

12

2

Port B pin as general I/O

3

Port B pin as general I/O

13

Port B pin used as general I/O

14

Component

LCD

Piezo sensor

Wind sensor

pH sensor

L293D

L293D

Temp. sensor

Zigbee module

Zigbee module

Ultrasonic sensor

Component Pin

RS

EN

D0-D3

Motor(In)

Motor(In)

D0

Rx

Tx

Echo pin

Trigger pin

Wi-Fi module CC2500 a wireless transceiver help to transmit the parameters of water pH, temperature. Wind sensor

measured by ATMEGA328 from DS18B220, CSL 31 sensors respectively to the controller of AEMV. According to

these values status of aqua water is detected by AEMV.

IC L293D is used to drive the DC motor.[9] A 5V supply is directly used as Enable input for the Driver IC. Also we

have used pins 15, 16, A5 and A4 to control the backward and forward motion of DC motors. The purpose of these

technique is to control the movement of AEMV.

A 16X2 LCD display in 4 bit mode is used to display the status of temperature and pH sensor and wind speed. Data

lines of LCD from D0-D3 are connected to the port pins 11,6,5,4 respectively. Pin no. 17 is used for Enable input of

LCD. And RS is given to pin no. 18 of ATmega 328.

Another important concept of our project is obstacle avoidance coming in the way ofAEMV. Echo pin and trigger

pin is connected to 13 and 14 pin of ATmega 328 microcontroller respectively. Whenever an obstacle comes at a

distance of 2 feet’s the microcontroller sends a warning to the controller of AEMV and if the vehicle is too close to

obstacle at distance minimum than 20cmAEMV automatically starts move in backward direction for 5 seconds and

alert the operator to change the direction of AEMV, which gives enough distance to the AEMV to avoid the

obstacle.

PCB Design of the implemented Circuit

1091

�ISSN: 2320-5407

Int. J. Adv. Res. 6(5), 1086-1095

Figure(5):- Circuit diagram of Arduino PCBS

B. System Software design and Implementation:

Main Flow chart of overall system Software implementation of the system is as shown in the flow chart of figure 6.

START

Measure Temperature value, display on LCD and send to the

controller (1000 ms delay)

Measure pH value, display on LCD and send to the controller (1000 ms delay)

Measure wind speed, DC voltage and send to the controller (2000 ms delay)

If the piezo

voltage is

generated

Send Obstacle warning

to controller

Send turbulence

warning to controller

Obstacle

Detection

Figure(6):- Main Software implementation of the system

Receive data from controller to control AEMV

Flowchart consists of three sub routines as stated further.

a. Sub routine for pH sensor.

b. Sub routine for Piezo-electric sensor.

c. Sub routine for Ultrasonic sensor.

Aquatic ecosystem monitoring vehicle starts its operation by taking the readings from temperature pH of water, and

voltage corresponding to wind speed sequentially. These measured value are displayed on16x2 LCD and then

transmitted to AEMV controller via wireless module CC2500. The samples are taken every one second. After this

the program control checks regularly for turbulence and presence of obstacle warning every 2 and 5 sec respectively

which then are sent wirelessly to AEMV. For obstacle too close to AEMV, it automatically reverses AEMV to avoid

accident and give enough distance to AEMV to change its direction.

1) Decision Flow chart of pH sensor

Sensor used to measure the pH value of water is CSL 31 which is an analog sensor gives voltage variations as an

output which is again mapped from 0 to 1023 by using internal 10 bit ADC of ATmega 328. For output is zero, <7,

and >7 the pH reading corresponds to neutral, Acidic and Alkaline nature of water respectively. Resolution of pH

sensor is 0.05.

1092

�ISSN: 2320-5407

Int. J. Adv. Res. 6(5), 1086-1095

START

Take reading p from pH sensor

If p==0

pH=7

If p>0

p<14

1

pH=7.05 to pH=14

p>140

p<281

pH=6.95 to

pH=0

Figure(7):- Flow chart of pH sensor

Results and Discussions:1) DS18B20 Result:

The temperature readings are taken using DS18B20 with respect to normal room temperature and higher

temperature readings are taken with respect to heated water. The observation table of measured values with

comparison of thermometer values is given below. The accuracy of DS18B20 is +/-1%. –Error obtained is in

the range of -0.68% to 0.59% which is within ±1%.

TABLE III:- Measured Temperature Readings and Error Computation

Sr. No

1

2

3

4

Sensor Value

28.69

29.81

33.51

39.16

Thermo. Value

28.63

29.80

33.53

39.13

%Error

-0.314

-0.34

0.59

-0.77

5

42.63

42.60

-0.70

6

53.21

53.23

0.37

7

73.31

73.26

-0.68

2) pH Sensor Result:

The pH readings are taken with respect to different acids and bases such as HCL, KCl, H2SO4, NaOH, KOH

etc. The different readings taken by pH sensor are compared by the traditional method of burette and conical

flask method as stated in Table III. Error Range obtained is within ±-3.28 to 2.38%.

TABLE IIIII:- Measured pH Readings and Error Computation

Sr. No

1

2

3

Sensor Value

0

27

67

Mapped Value

7.00

8.35

10.85

Traditional Method

7.06

8.37

10.98

%Error

0.85

2.38

1.18

4

83

11.15

11.27

1.06

5

223

2.85

2.74

-3.28

6

210

3.10

3.01

-2.99

7

157

6.15

6.11

0.65

1093

�ISSN: 2320-5407

Int. J. Adv. Res. 6(5), 1086-1095

3) AEMV Results:

AEMV is integrated with different analog and digital sensors. Readings taken by the various AEMV unit sensors are

transmitted using wireless system to the controller or supervisor continuously. Figure 8 shows the full system Set

up. The readings taken by temperature sensor DS18B20 and pH sensor CSL 31 are shown on 16x2 LCD display of

in Figure9.

Figure(8):- 8 Full system Set up

Figure(9):- Measured temperature and pH

sensor reading display.

4) Wireless module CC2500 on Hyper Terminal

The data from AEMV is transmitted to supervisor using wireless module CC2500 which uses 2.4 GHz ISM band.

CC2500 module is used as a transceiver antenna which transmitts and receives data simulateously. The data

transmitted via CC2500 module is received by receiver antenna connected to CH341SER module which converts the

serially received data into supportable universal serial system of USB drivers. CH341SER is connected to USB port

of personal computer from which the data is received and transmitted.

Figure(10):- Data received on a HyperTerminal

HyperTerminal is a open source free software which is used as a intermediate media between received data and

personal computer. HyperTerminal is used to show the received data i.e temperature value, pH value, wind speed in

meter/seconds, generated DC voltage, terbulance and warning if an obstacle comes in front ofAEMV. Figure 10.

represents the data received on a HyperTerminal.

Conclusion & Future Scope:Remotely operated unmanned vehicle is implemented for monitoring, protecting and maintaining the Aquatic

Ecosystem which is polluted due to waste chemicals from factories, oil spilling, accidents caused due to ships etc. It

is found to provide a suitable solution to solve this aquatic problems. As the research in this field enhances and other

innovations are introduced into the operations of unmanned underwater vehicles (UUVs), Underwater Vehicles and

make more common and highly cost effective.

Future Scope:

To install the device in the field, solar energy is a eco-friendly solution to meet the continuous power supply

requirement for working of AEMV .

For the transmission of the data from the field to the control room and Pollution Control Department internet

can be used for storing the data on cloud.

1094

�ISSN: 2320-5407

Int. J. Adv. Res. 6(5), 1086-1095

For the centralized data storage and also for the data maintenance we can use cloud computing and also we

can develop the android application for the interfacing of the data.

References:-

Anuradha A. Maindalkar, Saniya M. Ansari, “Aquatic Robot Design for Water Pollutants Monitoring”,

International Journal on Recent and Innovation Trends in Computing and Communication – June 2015 Volume

3 Issue 6 ISSN: 2321- 8169. (3-1)

2. Arnab Kumar Saha, Subhronil Roy, Aranya Himadri Nath Saha Bhattacharya, Prabhat Shankar, Anindya

Kumar Sarkar Pratanu Dasgupta “A Low Cost Remote Controlled Underwater Rover Using Raspberry Pi”,

978-1-5386-4649-6/18/$31.00 ©2018 IEEE ,pg.769-772

3. G.Divya Priya and Mr. I.Harish, “Raspberry PI Based Underwater Vehicle for Monitoring Aquatic

Ecosystem”, International Journal of Engineering Trends and Applications - March 2015-Vol 2 Issue 2 - ISSN:

2393 – 9516.(1-2)

4. Koushik Reddy, Vivek Kumar, “Cyber Aqua Culture Monitoring System Using Arduino And Raspberry Pi”,

International Journal of Advanced Research in Electrical, Electronics and Instrumentation Engineering- April

2015-Vol 4 Issue 5 - ISSN: 2278 – 8875.(2-3)

5. N.D. Jayasundere, S.H.K.K. Gunawickrama, (2016), “Under-water ROV with Fuzzy Logic Motion Control”,

Information and Automation for sustainability(ICIAfS),2016, 978-1-5090-6132-7/16/$31.00 ©2016 IEEE

6. Xuri Yu a ,Tommy Dickey a, *, James Bellingham b, Derek Manov a, Knut Streitlien, “The application of

autonomous underwater vehicles for interdisciplinary measurements in Massachusetts and Cape Cod Bays”,

Continental Shelf Research 22 (2002) 2225–2245, 0278-4343/02/$ - see front matterr2002 Elsevier Science

Ltd. All rights reserved.PII: S0278 -4343(02 )0 0070-5,pg 2225-2244.

7. Atmel 8-bit AVR Microcontrollers ATmega328/P Datasheet,

http://ww1.microchip.com/downloads/en/DeviceDoc/Atmel-42735-8-bit-AVR-Microcontroller-ATmega328328P_Datasheet.pdf

8. https://www.amazon.in/pH-Electrode-BNC-Combined/dp/B01DNE8C5O

9. http://www.ti.com/lit/ds/symlink/l293.pdf

10. http://www.alldatasheet.com/

11. https://www.electroschematics.com/8902/hc-sr04-datasheet/

1.

1095

�

IJAR Indexing

IJAR Indexing