Nylon 6

|

|

| Names | |

|---|---|

| IUPAC name

poly(hexano-6-lactam)

|

|

| Other names

polycaprolactam, polyamide 6, PA6, poly-ε-caproamide, Perlon, Capron, Ultramid, Akulon, Nylatron, Kapron, Alphalon, Tarnamid, Akromid, Frianyl, Schulamid, Durethan, Technyl

|

|

| Identifiers | |

| 25038-54-4 | |

| PubChem | 24850915 |

| Properties | |

| (C6H11NO)n | |

| Density | 1.084 g/mL |

| Melting point | 493 K |

| Vapor pressure | {{{value}}} |

|

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

|

|

| Infobox references | |

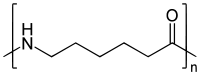

Nylon 6 or polycaprolactam is a polymer developed by Paul Schlack at IG Farben to reproduce the properties of nylon 6,6 without violating the patent on its production. It is a semicrystalline polyamide. Unlike most other nylons, nylon 6 is not a condensation polymer, but instead is formed by ring-opening polymerization; this makes it a special case in the comparison between condensation and addition polymers. Its competition with nylon 6,6 and the example it set have also shaped the economics of the synthetic fiber industry. It is sold under numerous trade names including Perlon (Germany), Nylatron, Capron, Ultramid, Akulon, Kapron (former Soviet Union and satellite states), and Durethan.

Synthesis

Nylon 6 can be modified using comonomers or stabilizers during polymerization to introduce new chain end or functional groups, which changes the reactivity and chemical properties. It’s often done to change its dyeability or flame retardance.[1] Nylon 6 is synthesized by ring-opening polymerization of caprolactam. Caprolactam has 6 carbons, hence 'Nylon 6'. When caprolactam is heated at about 533 K in an inert atmosphere of nitrogen for about 4-5 hours, the ring breaks and undergoes polymerization. Then the molten mass is passed through spinnerets to form fibres of Nylon 6.

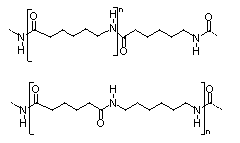

During polymerization, the amide bond within each caprolactam molecule is broken, with the active groups on each side re-forming two new bonds as the monomer becomes part of the polymer backbone. Unlike nylon 6,6, in which the direction of the amide bond reverses at each bond, all nylon 6 amide bonds lie in the same direction (see figure: note the N to C orientation of each amide bond).

Properties

Nylon 6 fibres are tough, possessing high tensile strength, as well as elasticity and lustre. They are wrinkleproof and highly resistant to abrasion and chemicals such as acids and alkalis. The fibres can absorb up to 2.4% of water, although this lowers tensile strength. The glass transition temperature of Nylon 6 is 47 °C.

As a synthetic fiber, Nylon 6 is generally white but can be dyed to in a solution bath prior to production for different color results. Its tenacity is between 6 and 8.5 gm/den with a density of 1.14 gm/cc. Its melting point is at 215°C and can protect heat up to 150°C on average.[2]

Applications

In 2010 over 4 million tons of polyamide 6 were produced. 60% of 2008 production went to fibre applications, engineering resins took 30% and films 10%. [1] Nylon 6 finds application in a broad range of products requiring materials of high strength. It is widely used for gears, fittings, and bearings, in automotive industry for underthehood parts, and as a material for power tools housings.[2] Nylon 6 is used as thread in bristles for toothbrushes, surgical sutures, and strings for acoustic and classical musical instruments, including guitars, sitars, violins, violas, and cellos. It is also used in the manufacture of a large variety of threads, ropes, filaments, nets, and tire cords, as well as hosiery and knitted garments. It can also be used in gun frames, such as those used by Glock, which are made with a composite of Nylon 6 and other polymers. In manufacturing, Nylon 6 is used as washers.[3] It has the potential to be reused as a technical raw material for the production of new Nylon 6, by depolymerization to caprolactam.[3]

Polyamide 6 (Nylon 6), especially glass fibre grades, can be effectively fire retarded with halogen free products. Phosphorus-based flame retardant systems are used in these fire-safe polymers and are based on aluminium diethyl phosphinate and synergists. They are designed to meet UL 94 flammability tests as well as Glow Wire Ignition Tests (GWIT), Glow Wire Flammability Test (GWFI) and Comparative Tracking Index (CTI). Main applications are in the electrical and electronics (E&E) industry.

Biodegradation

Flavobacterium sp. [85] and Pseudomonas sp. (NK87) degrade oligomers of Nylon 6, but not polymers. Certain white rot fungal strains can also degrade Nylon 6 through oxidation.Compared to aliphatic polyesters, Nylon 6 has poor biodegradability. Strong interchain interactions from hydrogen bonds between molecular nylon chains is said to be the cause by some sources.[4]

References

- ↑ ”Synthesis of Modified Polyamides (Nylon 6)”, NPTEL (National Programme On Technology Enhanced Learning), retrieved May 9, 2016

- ↑ ”Polyamide Fiber Phyisical and Chemical Properties of Nylon 6”, textilefashionstudy.com, retrieved May 9, 2016.

- ↑ ”Nylon”, New Process, retrieved May 9, 2016

- ↑ Lua error in package.lua at line 80: module 'strict' not found.

External links

- Articles without EBI source

- Chemicals that do not have a ChemSpider ID assigned

- Articles without KEGG source

- Articles without InChI source

- Articles without UNII source

- Chemical articles using a fixed chemical formula

- Articles containing unverified chemical infoboxes

- Polyamides

- Plastics

- Synthetic fibers

- German inventions