UHPC by Benjamin Graybeal

Materials and Structures, 2024

The setting behavior of ultra-high performance concrete (UHPC) is demonstrably different from tha... more The setting behavior of ultra-high performance concrete (UHPC) is demonstrably different from that of conventional concrete; thus, tools and guidance extending beyond common test methods such as Vicat and penetration are needed. While UHPC is known for its enhanced mechanical and durability properties, due to the low water and high cementitious contents, UHPC-class materials are prone to early-age autogenous shrinkage. Recognizing that UHPCs are commonly supplied to construction sites as prebagged, proprietary mixes with unknown constituents, and that accurate determination of setting time is crucial in determining the early-age autogenous shrinkage of UHPC-class materials as well as for scheduling construction operations and quality control actions, this study explores alternate test methods such as isothermal calorimetry (ASTM C1679),

semi-adiabatic calorimetry (ASTM C1753), autogenous shrinkage (ASTM C1698), chemical shrinkage (ASTM C1608), and dual ring test (American Association of State Highway and Transportation Officials (AASHTO T 363) to evaluate the setting behavior of UHPCs. Setting times obtained using the alternate test methods aligned well with each other and were found

to be different than the setting times indicated through standard test methods. Discussion and guidance on the applicability and the use of alternate test methods to determine the setting time of UHPCs for various laboratory and field applications are provided.

Design and Construction of UHPC-Based Bridge Preservation and Repair Solutions, 2022

This report is intended for bridge owners, contractors, and their supporting professionals respon... more This report is intended for bridge owners, contractors, and their supporting professionals responsible for design, construction, materials, and maintenance who are interested in including ultra-high performance concrete (UHPC) in their bridge preservation and repair (P&R) toolkit. This document aims to familiarize the reader with the material mechanical and durability properties of UHPC, along with common and emerging UHPC-based P&R solutions. Most notably, the document contains design and construction recommendations for three promising and fastest growing UHPC P&R applications: bridge deck overlays for rehabilitation, link slabs, and steel beam end repair. These recommendations are limited in scope but provide valuable information for all owner agencies considering the development of materials, construction, and design specifications. Lastly, much of the information provided herein builds on previous UHPC design and construction documents published by the Federal Highway Administration in Design and Construction of Field-Cast UHPC Connections (Report No. FHWA-HRT-19-011).

Properties and Behavior of UHPC-Class Materials, 2018

Ultra-high performance concrete (UHPC) is being adopted for a variety of different bridge constru... more Ultra-high performance concrete (UHPC) is being adopted for a variety of different bridge construction and rehabilitation applications. In North America, the most popular application of UHPC in bridge construction is for field-cast closure pours between adjacent prefabricated bridge elements, which are employed in many accelerated bridge construction (ABC) projects; this application has proven to be a common entry point for many bridge owners. As the demand for this innovative class of materials increases, so will the need for knowledge regarding the material properties and material characteristics. To fill this knowledge gap, researchers at Federal Highway Administration’s (FHWA’s) Turner-Fairbank Highway Research Center (TFHRC) executed an experimental study on six different commercially-available materials being marketed as “UHPC-class”. The goal of the research was to provide the bridge engineering community with a more comprehensive set of properties for this class of materials, which in turn could facilitate broader use within the sector. The UHPC-class materials were evaluated using 14 different ASTM, AASHTO, or FHWA-TFHRC-developed test methods. Results indicate that these materials behave similarly with respect to some performance measures such as compressive strength, tensile strength, and durability, but vary with respect to others such as dimensional stability, bond to precast concrete, and compressive creep.

Ultra-High Performance Concrete (UHPC) Overlays: An Example of Lifecycle Cost Analysis, 2023

There are two challenges to broader adoption of UHPC overlays: lack of long-term in-service perfo... more There are two challenges to broader adoption of UHPC overlays: lack of long-term in-service performance data and high initial material cost of UHPC relative to other bridge deck overlay materials. This document provides information addressing the latter challenge. The lifecycle cost analysis (LCCA) can be used to counter arguments against the high initial material costs of UHPC overlays. This document presents a summary of an LCCA study that was performed by a signature bridge owner evaluating different overlay options for one of their bridges. The analysis compared UHPC overlays with several thicknesses with conventional concrete overlay solutions and complete deck replacement. The findings show the net present cost of the different solutions and a break-even analysis. Lastly, the study also represents an example of what bridge owners could do to create a project-specific cost comparison.

Materials and Structures, 2023

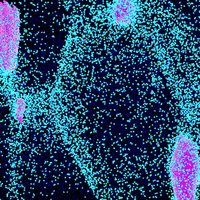

Ultra-high performance concrete (UHPC) is a class of concrete materials that has received signifi... more Ultra-high performance concrete (UHPC) is a class of concrete materials that has received significant attention from the infrastructure community due to its favorable mechanical and durability performance. As the use of UHPC in infrastructure projects is becoming more common, there is an increasing interest in identifying appropriate testing techniques to assess the durability properties of UHPC-class materials. The dense microstructure of UHPC-class materials and the presence of a high concentration of fiber reinforcement have made it difficult to rely on existing standard testing approaches for concrete durability assessment. This study explores the application of various conventional concrete durability test methods to UHPC, including electrical resistivity (American Association of State Highway and Transportation Officials (AASHTO) TP 119-22), freeze-thaw (ASTM C666), water absorption (ASTM C1585), and rapid chloride migration test (NT BUILD 492). The selected tests are meant to qualify and quantify the microstructural penetrability of UHPC to ions and fluids, a surrogate property commonly used as an indicator of durability. The findings from this study indicate that electrical resistivity can be used as a durability indicator for UHPC-class materials. Moreover, strong correlation between electrical resistivity and the chloride migration coefficient is identified, a potential benefit given that chloride migration can be used to estimate service lives of UHPC-class materials. Other tests, including freeze–thaw and water absorption, although identifying the favorable performance of UHPC relative to conventional concrete, were unable to provide insightful information through which the performance of individual UHPCs could be differentiated.

Structural Design with Ultra-High Performance Concrete, 2023

UHPC is a structural material that exhibits compelling structural behaviors. These behaviors are ... more UHPC is a structural material that exhibits compelling structural behaviors. These behaviors are distinct from those exhibited by other more common materials used in the civil infrastructure, such as conventional concrete or steel. In comparison to conventional concrete, UHPC offers sustained postcracking tensile resistance, along with an increased compressive strength, an increased elastic modulus, and a decreased susceptibility to liquid permeation. To effectively engage the enhanced behaviors of UHPC, structural design guidance must rationally and conservatively provide a framework within which designers can appropriately conceive UHPC structures and proportion UHPC elements. With a look toward the future, UHPC can most likely allow for the design of novel structures whose composition is efficient, whose functionality is improved, and whose lifespan is extended. Until now, there has not been any formal design guidance in the United States for structural design with UHPC. Recent research and development-based advancements related to UHPC, and a growing interest from bridge owners in the possibilities presented by this material, have provided an opportunity for the bridge engineering community to consider and potentially adopt formal structural design guidance for UHPC structural elements. The main body of the report provides an overview of UHPC in the context of structural design. The report also contains three appendices. The first, Appendix A—Guide Specification for Structural Design with Ultra-High Performance Concrete, contains a draft structural design framework developed for consideration by AASHTO and presented in the format commonly used for AASHTO guide specifications. Section 1 of Appendix A focuses on structural design guidance, while Section 2 focuses material conformance guidance. To assist readers in understanding the potential application of the proposed structural design framework, a pair of design examples has been developed to demonstrate some of the basic concepts embedded in the framework. The first example focuses on using the methods in the design framework to analyze the behavior of a rectangular beam. This example can be found in Appendix B—Analysis of a Rectangular, Mild Steel Reinforced UHPC Beam. The second example demonstrates the design of a slab-on-stringer bridge superstructure using pretensioned girders. This example can be found in Appendix C—Design Example of a Pretensioned UHPC I-Beam Bridge with a Conventional Concrete Deck.

United States. Federal Highway Administration, 2010

This TechBrief highlights the results of a research program that developed finite element analysi... more This TechBrief highlights the results of a research program that developed finite element analysis modeling techniques applicable to ultra-high performance concrete (UHPC) structural components.

Journal of Structural Engineering, 2022

Because of their tensile strain-hardening characteristics, ultrahigh-performance concrete (UHPC) ... more Because of their tensile strain-hardening characteristics, ultrahigh-performance concrete (UHPC) materials offer significant advantages in terms of beam shear capacity and postcracking behavior compared to conventional reinforced-concrete beams. These advantages rely on UHPC's ability to sustain its strain-hardening characteristics at the structural level. This paper reports the results of an experimental investigation on the parameters influencing the structural shear behavior of prestressed UHPC bridge girders. Six pretensioned bulb-tee UHPC bridge girders were tested in shear with the following test variables: the UHPC material properties, the girder height, the web thickness, the number of prestressing strands, and the presence of discrete transverse steel reinforcement in the web. The average relationship between the principal stress and strains in the web was monitored during the tests and compared to behavior obtained from uniaxial tests. The shear behavior and capacities of the tested girders were observed to be largely dependent on the tensile characteristics of UHPC. The results demonstrate UHPC's capability to sustain its strain-hardening characteristics at the structural scale and highlight the importance of the crack localization strain, corresponding to the end of the tensile hardening behavior, to the global shear performance of UHPC girders.

Journal of Structural Engineering, 2022

Beams made of ultrahigh-performance concrete (UHPC), a fiber-reinforced concrete with high compre... more Beams made of ultrahigh-performance concrete (UHPC), a fiber-reinforced concrete with high compressive strength and tensile strain-hardening characteristics, exhibit flexural behaviors that are different than those traditionally associated with steel-reinforced conventional concrete beams. These behaviors necessitate the development of new predictive design tools that reflect the effect of the material-level properties on the flexural behavior. The research presented in this paper assessed the flexural behavior of UHPC beams through the displacement-controlled testing of a prestressed UHPC bridge girder to failure. The girder was 18.90 m (62 ft) long and contained a total of 26 17.8-mm-(0.7-in.)-diameter steel strands and no mild steel reinforcement. The testing focused on capturing the intermediate and final behaviors, including first cracking, yielding of strands, moment capacity at the development of a single dominant crack, and rupture of strands. Building on observations from this study and prior research by the authors and others, a flexural design framework, founded on the concepts of equilibrium and strain compatibility, is proposed for beams made with UHPC and reinforced with conventional steel reinforcing bars, prestressing strands, or both. The proposed framework includes considerations to avoid the local straining and subsequent hinging of UHPC beams and to address the ductility of flexural members. The framework is verified by comparing the experimental results of flexural tests performed by the authors and others to the analytical predictions, which predominantly relied on input material parameters obtained from independent material tests.

Engineering Structures, 2010

Ultrahigh-performance fiber-reinforced concrete (UHPFRC) is an innovative material in the field o... more Ultrahigh-performance fiber-reinforced concrete (UHPFRC) is an innovative material in the field of bridge engineering. With superior mechanical characteristics, this new material reduced the structural self-weight and extended the span of modern bridges. A series of tests should be conducted to establish reliable design rules for UHPFRC structures. is paper aimed at determining the compressive behavior of UHPFRC for thin-walled arch section design and a comparison was made with a normal concrete (NC) arch. Eighteen axial compression columns for arch section design and arches under asymmetric load were tested in this paper. Behaviors of the arches were assessed using various mechanical properties, including the failure pattern, load-deflection relationship, strain analysis, and analytical investigation. A finite element model (FEM) considering the material and geometric nonlinearity was developed to predict the behavior of the UHPFRC arch. Results indicated that a wall thickness of 50 mm with stirrups effectively restrained instability failure of the thin-walled compression columns. e cracking load and the ultimate load of the UHPFRC arch increased by 60% and 34%, respectively, when comparing with the NC arch. It showed the UHPFRC arch had higher load capacity and outstanding durability. e failure mode of the UHPFRC arch was similar to that of the NC arch, which belonging to the destruction of multihinges. However, the appearance of the plastic hinges was delayed, and a better elastic-plastic performance was obtained when using UHPFRC. e analytical formula for calculating the ultimate load of the UHPFRC arch was derived with high precision by using the limit equilibrium method. e results of the FEM showed good agreement with test results, and they were able to predict the behavior of the UHPFRC arches.

Second International Interactive Symposium on UHPC

To date, very little research has been conducted on the interface shear behavior of UHPC-class ma... more To date, very little research has been conducted on the interface shear behavior of UHPC-class materials. The structural concrete research group at FHWA's Turner-Fairbank Highway Research Center is currently developing an experimental program to evaluate the interface shear behavior of this class of materials. The primary goal of this presentation is to provide some preliminary

Ultra-High Performance Concrete (UHPC) is a relatively new class of advanced cementitious composi... more Ultra-High Performance Concrete (UHPC) is a relatively new class of advanced cementitious composite materials, which exhibits high compressive [above 21.7 ksi (150 MPa)] and tensile [above 0.72 ksi (5 MPa)] strengths. The discrete steel fiber reinforcement included in UHPC allows the concrete to maintain tensile capacity beyond cracking of the cementitious matrix. The combination of the matrix and fiber performance allow for a reduction on the development length of reinforcing bar, thus providing the potential for a redesign of some structural systems such as field–cast connections between prefabricated bridge elements. The bond behavior of deformed reinforcing bar in UHPC is investigated in this study by conducting direct tension pullout tests. Over 200 tests were completed and the effects of embedment length, concrete cover, bar spacing, concrete strength, bar size and type on bond strength were investigated. It was found that the development length of embedded reinforcement in UH...

Recent advances in concrete materials have led to a new generation of cementitious materials, nam... more Recent advances in concrete materials have led to a new generation of cementitious materials, namely ultra-high performance concrete (UHPC). This concrete possesses advanced properties in terms of compressive behavior, durability, and tensile load carrying capacity. UHPC attains these behaviors via an optimized gradation of cementitious materials, chemical admixtures, and steel fiber reinforcement. Past research conducted by the Federal Highway Administration has characterized the static moment and shear resistance of UHPC superstructure members. The current project aims to investigate the behavior of an AASHTO Type II prestressed girder under repeated cyclic loading. In this test program, the upper limit of the applied cyclic loads is just below the static load levels that would cause flexural and shear cracking of the girder. The specimen endured 12 million cycles without failure and the test was terminated. Cracks were first observed in the cementitious composite after 0.64 milli...

Ultra-high performance concrete (UHPC) is an advanced cementitious composite material, which tend... more Ultra-high performance concrete (UHPC) is an advanced cementitious composite material, which tends to exhibit superior properties such as exceptional durability, increased strength, and long-term stability. The use of existing structural configurations for materials with advanced properties results in inefficient designs and less cost-effective solutions. Therefore, the purpose of this research is to develop a series of optimized sections of UHPC pi-girders to effectively utilize the superior mechanical properties of UHPC over longer span lengths through finite element analysis (FEA).

Ultra-high performance concrete (UHPC) is an emerging construction material that has been demonst... more Ultra-high performance concrete (UHPC) is an emerging construction material that has been demonstrated to advance the state of the art for construction of prefabricated bridge elements and systems (PBES). Specifically, UHPC allows for significant simplifications in the design of the component connections, while simultaneously affording enhanced durability and simplified construction practices. As of early 2012, 18 bridges in the United States and Canada have been constructed using field-cast UHPC connections, and this note displays two of those bridges. The first bridge shown is the first bridge in the United States to use field-cast UHPC connections. Eight simple span deck-bulb- tee girders were joined with non-contact lap splice deck-level connections. The second bridge has precast concrete deck panels and field-cast UHPC connections. However, as with any new technology, initial deployments of field-cast UHPC technology face hurdles relating to inevitable construction process chan...

This study investigated the development length of 0.5- and 0.6-inch (12.7- and 15.2-mm) diameter ... more This study investigated the development length of 0.5- and 0.6-inch (12.7- and 15.2-mm) diameter untensioned prestressing strands embedded in steel fiber and polyvinyl alcohol (PVA) fiber reinforced UHPC. The volumetric fiber content was 2 percent. The compressive strength of the steel fiber reinforced UHPC at the time of strand splice testing was approximately 23.5 ksi (162 MPa). As is common when reduced stiffness fibers are used in UHPC, the compressive strength of the PVA fiber reinforced UHPC was reduced to a value of approximately 19.5 ksi (134 MPa). A development length test was designed that allowed for the replication of the tension-tension stress state that could occur when two strands were lap spliced within a connection between two linear elements.

This document is a technical summary of the unpublished Federal Highway Administration (FHWA) rep... more This document is a technical summary of the unpublished Federal Highway Administration (FHWA) report Behavior of Field-Cast Ultra-High Performance Concrete Bridge Deck Connections Under Cyclic and Static Structural Loading, which is available through the National Technical Information Service (NTIS), www.ntis.gov. The TechBrief highlights the results of a study aimed at evaluating the performance of field-cast ultra-high performance concrete (UHPC) connections linking precast concrete bridge deck components.

This document is a technical summary of the unpublished Federal Highway Administration report, Hi... more This document is a technical summary of the unpublished Federal Highway Administration report, High Performance Concrete Bridge Deck Investigation, available only through the National Technical Information Service (NTIS). NTIS Accession No. of the report covered in this TechBrief: PB2009-115497. This TechBrief provides a summary of an investigation that assessed the performance of high performance concrete (HPC) bridge decks. HPC is a concrete designed to meet a performance specification. Many definitions of HPC have been proposed over the past 15–20 years; one to note is the definition proposed by Goodspeed and later expanded by Russell and Ozyildirim that offers a series of strength and durability-related performance characteristics. It recommends that the desired performance of the concrete should be considered and that the performance characteristics should then be set accordingly. Example performance characteristics toward which concrete properties may be focused include chlori...

Second International Interactive Symposium on UHPC

The longest current pretensioned bridge girders are approximately 200 ft (61.0 m) long, with this... more The longest current pretensioned bridge girders are approximately 200 ft (61.0 m) long, with this limit being controlled by concrete mechanical properties, prestressing strand capabilities, and shipping/handling considerations. With compressive strength greater than 21.7 ksi (150 MPa) and sustained post-cracking direct tensile capacity exceeding 1.0 ksi (6.9 MPa), ultra-high performance concrete (UHPC) has emerged as new class of cementitious composites, unlocking opportunities for longer spans and structural optimization of bridge girders. This study builds on extensive research completed at the Federal Highway Administration's Turner-Fairbank Highway Research Center to explore the viability of a 300 ft (91.4 m) single span pretensioned prestressed girder made with UHPC. The paper outlines the material modeling approaches, directly derived from experimental data, and utilizes the concept of strain compatibility to determine the flexural capacity and possible failure modes of the girder. The shear design approach is based on principal tensile stress trajectories to address the shear failure mode caused by a diagonal field of tensile forces in web of the girder. The shear capacity is then related to the tension strength of UHPC and the expected failure plane angles. By investigating these primary demands on the girder, this work demonstrates that the proposed cross section is a viable solution. The paper constitutes a discussion of UHPC bridge girder behavior and provides designers with insight on key aspects of the design procedure.

Uploads

UHPC by Benjamin Graybeal

semi-adiabatic calorimetry (ASTM C1753), autogenous shrinkage (ASTM C1698), chemical shrinkage (ASTM C1608), and dual ring test (American Association of State Highway and Transportation Officials (AASHTO T 363) to evaluate the setting behavior of UHPCs. Setting times obtained using the alternate test methods aligned well with each other and were found

to be different than the setting times indicated through standard test methods. Discussion and guidance on the applicability and the use of alternate test methods to determine the setting time of UHPCs for various laboratory and field applications are provided.

semi-adiabatic calorimetry (ASTM C1753), autogenous shrinkage (ASTM C1698), chemical shrinkage (ASTM C1608), and dual ring test (American Association of State Highway and Transportation Officials (AASHTO T 363) to evaluate the setting behavior of UHPCs. Setting times obtained using the alternate test methods aligned well with each other and were found

to be different than the setting times indicated through standard test methods. Discussion and guidance on the applicability and the use of alternate test methods to determine the setting time of UHPCs for various laboratory and field applications are provided.

Ten inspection tasks were performed at seven test bridges using State bridge inspectors. The sample of participating inspectors included 49 inspectors from 25 State agencies. Inspectors were provided with common information, instruction, and tools. Inspector characteristics were measured through self-report questionnaires, interviews, and direct measurements.

Routine Inspections were completed with significant variability, and the Condition Ratings assigned varied over a range of up to five different ratings. It is predicted that only 68 percent of the Condition Ratings will vary within one rating point of the average, and 95 percent will vary within two points. Factors that appeared to correlate with Routine Inspection results include Fear of Traffic; Visual Acuity and Color Vision; Light Intensity; Inspector Rushed Level; and perceptions of Maintenance, Complexity, and Accessibility.

In-Depth Inspections using Visual Inspection alone are not likely to detect or identify the specific types of defects for which the inspection is prescribed, and may not reveal deficiencies beyond those that could be noted during a Routine Inspection. The overall thoroughness with which inspectors completed one of the In-Depth tasks tended to have an impact on the likelihood of an inspector detecting weld crack indications. Other factors that may be related to In-Depth Inspection accuracy include: time to complete inspection, comfort with access equipment and heights, structure complexity and accessibility, viewing of welds, flashlight use, and number of annual inspections performed.

The State procedural and reporting tasks indicated that most States follow similar procedural and reporting criteria. Several inconsistencies were noted with the use of the element-level inspection systems, but it is not known if these variations are the result of State practices or inspector use. Deck delamination surveys were found to have significant variability, with only a few teams performing a delamination survey as part of the Routine Inspection.

The simultaneous application of structural and environmental loadings to a UHPC flexural member did not result in any apparent degradation of the member’s flexural capacity. The structural and environmental loading was conducted for 154 days during which 500,000 cycles were applied. NaCl solution ingress occurred, but no fiber reinforcement degradation was observed. Additionally, uniaxial tensile testing of UHPC prismatic sections was demonstrated as a viable means of assessing the tensile properties of this fiber-reinforced concrete.